If you are facing a promotion or additional responsibilities as a Machinery Dealer Department or Branch Manager or even a Division Executive, congratulations! You are anxious to get started and do the best job you can.

However, in many circumstances the challenges in this new position can be formidable. And, at first glance, the magnitude of problems in all directions can appear nearly impossible to overcome.

Here’s a field proven approach that can help guide you, assist you in establishing priorities, achieve success, and enable you to build and maintain a strong, positive relationship with your manager. The key to success in this new and challenging adventure is to make certain you and your boss are always on the same wavelength. That is, you and he/she are in total agreement on your priorities and action plans. This approach will foster and ensure their support for your efforts. Unless you build this bond, really bad things can happen.

One of the main reasons that your new responsibilities can be so exciting is because a dealership is a very complex combination of five separate businesses, loosely connected by internal relationships. The fundamental strategy for managing this type of highly complex system was developed several decades ago by organizing the dealership into Revenue Centers with separate monthly financial statements. Fortunately, today, there are well established performance benchmarks for the profit drivers in each machinery dealer revenue center. And, these can be invaluable tools in your problem diagnostics and problem solving efforts.

The problem solving process for the newly appointed Dealer Manager or Executive:

Step 1: IDENTIFY THE PROBLEMS

Diagnostic Tools: Quantitative and Qualitative Performance Analysis

The function of diagnostics is to identify performance gaps.

Just as in human health management, diagnostics play an essential role in assessing unhealthy business situations, identifying causes of problems, and indicating what remedies are most appropriate.

In diagnosing dealer business management problems, Quantitative analysis is like your blood test. Are you within the therapeutic or healthy range for critical performance areas? Instead of looking at cholesterol, liver enzymes, or blood cells, the dealer examines market shares, sales mix, gross profit margins, sales per employee, asset productivities, days in receivables or WIP, and revenue center contributions. Where should you be? What are your realistic targets? What therapies would work best for you?

Qualitative analysis enables the dealer to observe and consider Best Practices by high performance dealers. Which of these policies and procedures could most benefit your business? Which Best Practices could significantly help reduce or eliminate organizational performance problems and stimulate positive change?

Quantitative and Qualitative Diagnostics together provide a very clear understanding of your current conditions as well as guidelines toward the most appropriate remedial actions for you and your management team.

How to Do It:

A. Benchmark Critical Profit Variables. This step compares your quantitative performance scores to High-Profit dealers in your industry.

B. Audit Best Industry Practices. This step compares your operations with programs, policies and procedures of World Class dealers.

Complete the qualitative assessment diagnostic. Audit your operations with the Best Industry Practices checklist. Which of these programs, policies, and procedures could be helpful to you?

The two most comprehensive guides to Machinery Dealer Performance Benchmarks and World Class Machinery Dealer Best Practices are contained in my Achieving Excellence in Dealer/Distributor Performance and my Strategies Tactics, Operations for Achieving Dealer Excellence

Step 2. PRIORITIZE THE PROBLEMS

TRIAGE

“Determining the Severity of Condition and Priority of Treatment.”

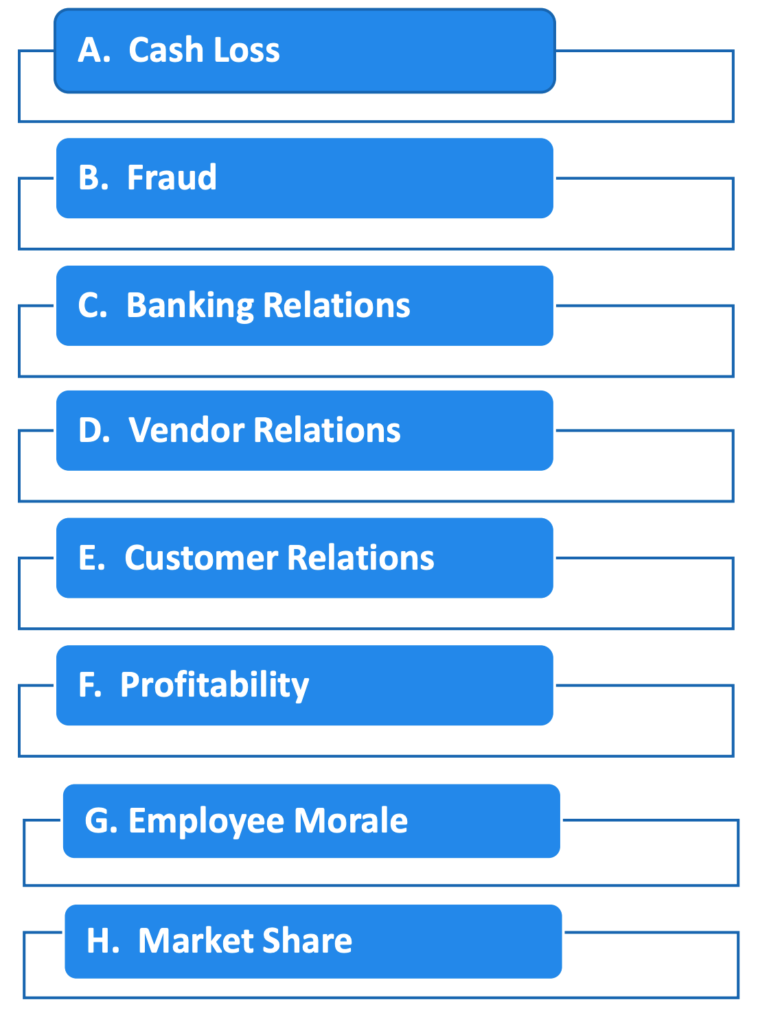

What must you do when things go awry in a dealership? If a body is hemorrhaging, the blood escaping from the circulatory system must be controlled and stopped. In a typical dealership, Operations Triage normally focuses on problems in the priority shown in Chart 1 below.:

According to this chart, if there are situations causing direct cash loss, these issues must be dealt with immediately, before Banking Relations or Vendor Relations issues. (Two additional potential problem areas are Safety and Community/ Public Relations).

As you perform this Operations Triage on your Revenue Center(s), you will prioritize problem severity. If you are a newly appointed Dealer Executive, do consider triage needs to be done on each revenue center, and from the overall dealership perspective as well.

How to Do It:

Prioritize your performance issues and problems. Which are causing the most grief?

Which are putting your business at most financial risk?

Chart: Dealer Operations Triage

Again, let me emphasize, the key to success in your new and challenging adventure is to make certain you and your boss are on the same wavelength. That is, you and he/she are in total agreement on your priorities and action plans. At this point in your assessment, prepare and present a formal “Current Situation and Recommended Remedial Actions” report.

Step 3. RESOLVE THE PROBLEMS

Once you have identified and prioritized the problem and structured corrective approaches, what does it really take to make it happen. How do you convert good intentions to reality?

In this third critical step there are resources to help ensure you achieve implementation. My Dealer Problem Solving Handbook text contains examination, discussion and solutions to nearly 200 dealership operations problems.

NOTE: At any point in your Problem Solving Process, please contact me for assistance, suggestions, and references to useful information: Walt@mcd.winsbystorage.com.